LSU-led Team Wins $7M E-RISE Award From the National Science Foundation

July 01, 2025

Supporting Farms and Chemical Manufacturing

Piles of sugarcane bagasse, an agricultural waste product, in Raceland, Louisiana.

First E-RISE grant to Louisiana will create jobs and solutions to transform agricultural wastes into liquid fuels for transportation, opening new revenue streams for Louisiana’s farmers and the state’s chemical industry.

The latest big energy win for LSU and Louisiana leverages both of the state’s leading industries and core research priorities for LSU—energy and agriculture.

“This extraordinary award, $7 million, shows how LSU researchers are creating solutions that support Louisiana’s economy, our farmers, and most important industries,” LSU Interim President Matt Lee said. “We continue to build strong teams that bring innovation and jobs and allow us to do what we do best—win for Louisiana.”

“Through this team’s research, Louisiana will make more diesel, jet fuel, and gasoline using biomass,” said John Flake, associate vice president of research and a professor of chemical engineering at LSU. “This is a natural fit for Louisiana for two reasons. We are kings of biomass, and we have the capacity to refine, blend, and ship liquid fuels. All huge advantages.”

LSU’s statewide team is led by Ingmar Schoegl, associate professor of mechanical engineering in the LSU College of Engineering, in partnership with Dorin Boldor, professor of biological and agricultural engineering in the LSU AgCenter with a joint appointment in the LSU College of Engineering. Education and research partners include Louisiana Tech University, Southern University, University of Louisiana at Lafayette, and River Parishes Community College, all of which already collaborate on research and workforce development as part of the LSU-led $160 million FUEL project, also funded by the National Science Foundation (NSF) and announced last year.

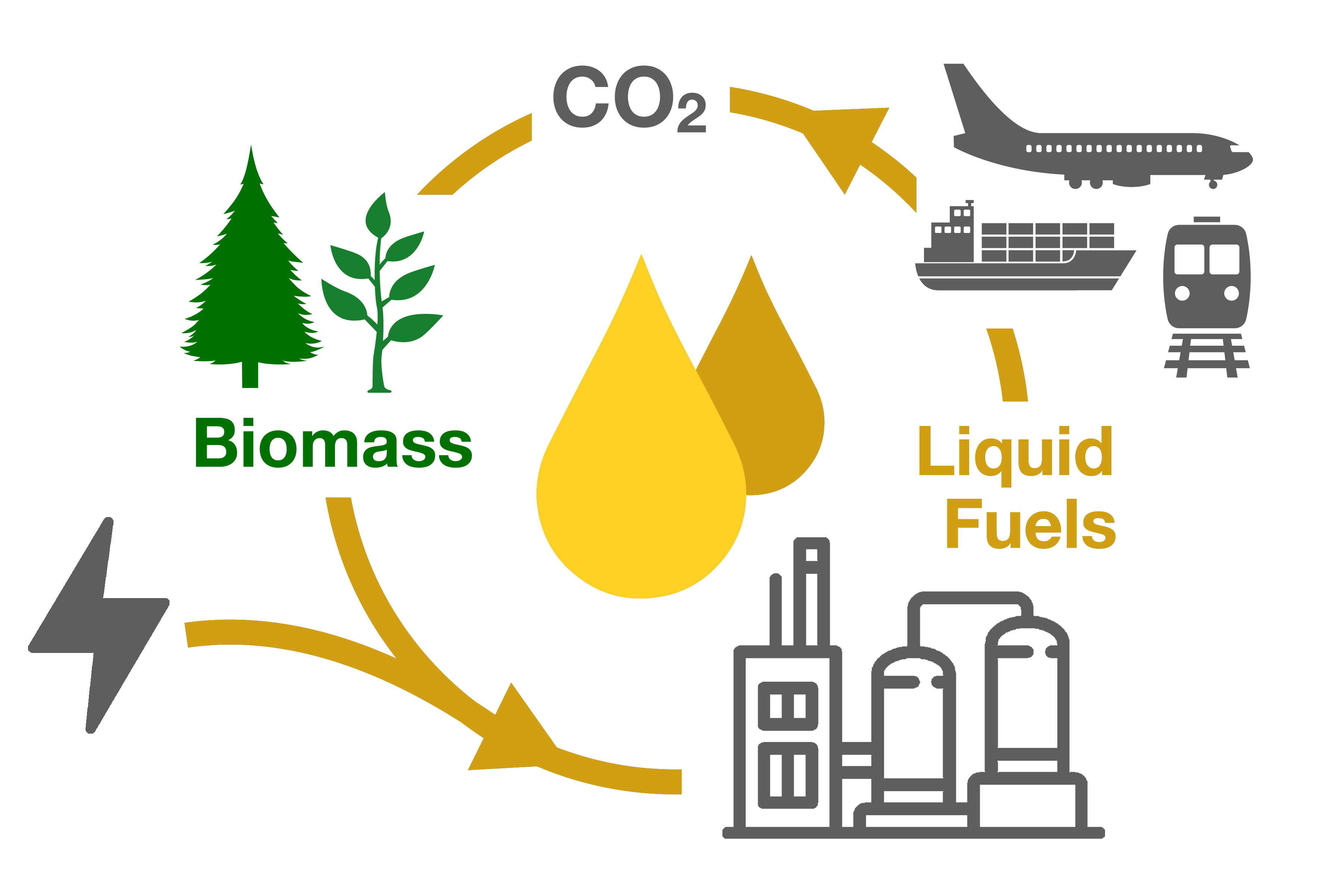

The LSU-led team will transform biomass and electricity into liquid fuels for transportation and train a bigger workforce to support bio-electric fuel technologies.

While FUEL works to position Louisiana as the world’s energy leader by helping the state produce more energy and more globally competitive chemicals and fuels, the team led by Schoegl is specifically focused on new ways to create liquid fuels from agricultural waste. Both projects leverage Louisiana’s plants, pipelines, ports, and people to drive energy innovation for economic impact.

Most of the state’s chemical manufacturing plants are located along the Mississippi River, which theoretically could collect more than 40% of the nation’s agricultural wastes by barge to Louisiana for processing into high-value liquid fuels. In Louisiana, the state’s leading producers of sugarcane, timber, and lumber could integrate new fuel production facilities with their existing processing plants and use their residual biomass to make fuels they can either sell or use in their own operations.

“This is all about linking up agriculture and the chemical industry here in Louisiana and turning waste into value,” Schoegl said. “Louisiana is like a switchboard with all the pipelines we have that distribute fuel across the country. So, we already have the existing infrastructure to make this work, and the Mississippi River that can transport products very efficiently. Basically, this is the most logical place to perform this research and make it practical and profitable for industry to use while educating a larger technical workforce to run it all.”

“The beauty of this project is that we couple two seemingly separate industries to create a new generation of products that can be used in the petrochemical industry in Louisiana,” Boldor said. “All the state’s sugar mills generate mountains and mountains of sugarcane bagasse, which is their leftover product. And it’s just sort of sitting, in the open field, because they can’t use it for anything—only a small fraction is used to power their operations during harvesting season. So, this is ripe for us to use as feedstocks in our processes, improved by the electrochemical technology that is being developed here at LSU.”

The educational partners on the winning team: LSU, LSU AgCenter, Louisiana Tech University, Southern University, University of Louisiana at Lafayette, and River Parishes Community College.

E-RISE is an acronym for EPSCoR Research Incubators for STEM Excellence. The full name of the NSF award is E-RISE RII, where the last three letters stand for Research Infrastructure Improvement, which includes teambuilding. LSU’s statewide team represents a wide variety of disciplines, from chemistry and chemical engineering to agriculture, computational modeling, and economic analysis.

“Joining this team marks a significant milestone for our institution,” said Donovan Thompson, dean of River Parishes Community College’s Energy Sciences Division and executive director of its Energy Partners for Innovation and Collaboration (EPIC) consortium. “Together with LSU and our partners, we’ll develop cutting-edge course modules and workshops focused on bio-electric fuel technologies—a field entirely new to our college’s curriculum—and provide students with hands-on, work-based learning experiences to prepare them to be leaders in the rapidly evolving energy expansion.”

“If you ride by any one of our 11 raw sugar mills throughout Louisiana, you’ll see mountains of sugarcane bagasse that has collected over the years. In total, about three million tons are added each harvest season. Bagasse is a waste product and expensive to move, and wherever it goes, it costs money to store or takes land out of production. This research project led by LSU to turn bagasse into fuel could make our state’s number-one row crop industry even more sustainable and profitable to keep us producing for another 200 years.”

Atticus Finger, director of research for the American Sugar Cane League

The novelty of Schoegl’s team’s research will be to combine electrochemical processing with biomass pyrolysis. Pyrolysis is the heating of an organic material, such as biomass, in the absence of oxygen. You typically get three products: a gas, a liquid, and a solid char residue. The liquid is usually separated into two fractions—a lighter part made up of mostly water, acids, and alcohols, and a heavier, oily part that is similar to petroleum. Historically, makers of biofuel or biodiesel have burned the gas, purged the light liquid, and used only the oil, with the char residue being discarded or added to soil. Schoegl’s team, meanwhile, will allow liquid fuels to be made from the gas and both parts of the liquid, while the char, which has a high carbon content, could be converted into other types of products.

Next Step

Discover stories showcasing LSU’s academic excellence, innovation, culture, and impact across Louisiana.