LSU Shreveport Cyber Collaboratory Develops High-Tech Tools and Talent in Northwest Louisiana, Finds New Partners

April 05, 2021

Through the new LSU Shreveport Cyber Collaboratory and partnerships between the university, Louisiana Economic Development (LED), the City of Shreveport, local K-12 schools, military, and industry—including small business—students are starting to see what it actually means to boost high-tech innovation in northwestern Louisiana.

LSUS senior Joshua Ricard and LSUS Cyber Collaboratory Director Scott Isaacs brought their new 3D scanner into the cockpit of a B-52 bomber on Barksdale Air Force Base this month to help the Air Force develop new virtual reality training programs for pilots.

– Senior Master Sgt. Ted Daigle, U.S. Air Force

LSU Shreveport (LSUS) senior Joshua Ricard is working toward a Bachelor of Fine Arts and a Bachelor of Science in digital, interactive design. He did not expect to be sitting in the pilot’s seat of a B-52 bomber last week, operating a $25,000 handheld digital 3D scanner trying to capture every detail of the plane’s yoke, which is what the pilot holds to steer the plane:

“I asked, ‘You want me to do what?”

Ever since the Collaboratory opened last year, each new tool the team has received and added to their lineup has revealed a new need in the larger Shreveport community.

“We got the scanner, had literally just unboxed it, and the next day got the question, ’Hey, can you help us with this?’ and, ‘Well, we’ve got this scanner…,’” Ricard remembers getting the call from Barksdale Air Force Base southeast of Bossier City. “It was maybe our third time using the scanner and working on the base was definitely a unique experience, walking up to this giant machine, getting to see where they store the bombs and then crawling up inside.”

To get a full 360-degree scan of the back of the yoke, Ricard had to pull it back, hard.

“We needed a clean scan without my hands in it, and B-52s are basically all manual and mechanical; there is very little electronic stuff, so when you pull on something, it has a direct correlation on something else,” Ricard said. “There’s no ‘press a button and it does all of the stuff for you.’ Everything takes effort.”

“It used to be that the military was on the cutting edge of R&D, which then trickled down to civilian sectors. But with technology advancing so quickly, this has now flipflopped, and it’s our job to transfer civilian technology to help solve military challenges by partnering with the innovators with the best solutions.”

STRIKEWERX Director Russ Mathers on his growing collaboration with LSUS (STRIKEWERX is the innovation hub of the Air Force Global Strike Command

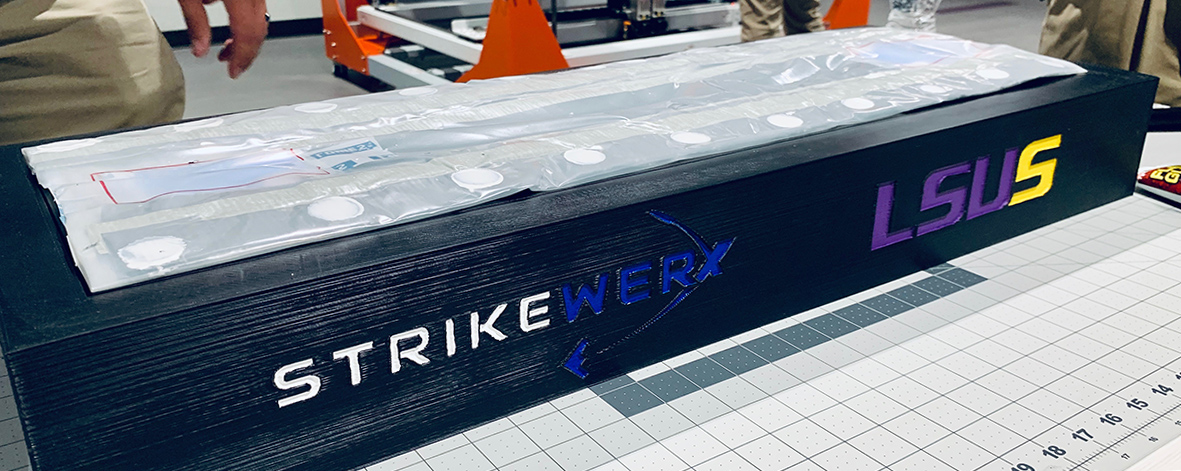

This was not Ricard’s first time working with the Air Force, however. Through STRIKEWERX, the innovation hub of the Air Force Global Strike Command, recently housed in the Cyber Innovation Center in Bossier City, he’d been pulled into two other projects already: modeling and 3D-printing custom covers for transporter erector jack slots for intercontinental ballistic missiles, or ICBMs, which had been filling up with dirt and snow, taking airmen hours to clean out. The other project was creating a custom jig for the Barksdale hydraulics shop so they could be precise in how they drill out pressure plates for brake shoes on B-52s, instead of eyeballing where the holes should go, risk missing the mark, and wasting expensive materials.

“It used to be that the military was on the cutting edge of R&D, which then trickled down to civilian sectors,” said STRIKEWERX Director Russ Mathers. “But with technology advancing so quickly, this has now flipflopped, and it’s our job to transfer civilian technology to help solve military challenges by partnering with the innovators with the best solutions.”

Since opening its doors last August, the LSUS Cyber Collaboratory team has found that each new high-tech tool it has brought in and added to its lineup has revealed a new need in the surrounding community. Director Scott Isaacs fields ideas for collaborative projects on a weekly, near-daily, basis.

STRIKEWERX and LSUS formalized their relationship last year. The Cyber Collaboratory is now about to engage in yet another Air Force project, which is to prototype, test, and produce 100 clear acrylic bins to help store and organize vaccine vials, including COVID-19 doses, in refrigerators in military (and possibly civilian; the design will be open-source) hospitals.

“Instead of building our own maker space and buying our own equipment, LSUS is doing a great job in finding white space in what’s out there already, and filling in that space,” Mathers said. “It’s cheaper and faster for us to partner with LSUS, and whether it’s their hologram table or 3D-printing or the new laser cutter they’re getting, the Cyber Collaboratory is providing the Air Force with capabilities and skills we need; things nobody else is doing. The idea for the vaccine bin came from one of our Airmen, a technical sergeant, and now LSUS is going to help us figure out how to actually produce it.”

Before the Cyber Collaboratory opened its doors last year, students and staff had already been putting its brand-new 3D printers to use in making personal protective equipment, or PPE, for the surrounding community, including custom head straps for face shields. The Collaboratory received support for the face shield project from the American Electric Power (AEP) Foundation, which also provided significant funds toward professional development and equipment. (Some of the PPE funds will now be repurposed for the COVID-19 vaccine bin project.)

“We had all of these new tools and the pandemic had basically shut everything else down, so the obvious question was, ‘What can we do for the community?’” recalls graduate assistant in the Cyber Collaboratory and master’s student in counseling Matthew Dixon. “Creative problem solving starts with a need, and a lot of what we do is coming up with right-now solutions. We must have printed close to 2,000 head straps and that was my first hands-on experience with 3D printing.”

When Eric Rippetoe, founder of the physical therapy company Bishop in Shreveport, connected with a high-impact sports client whose leg was larger than the print bed of his own 3D printer (Bishop creates custom knee braces through 3D printing and design), he reached out to the LSUS Cyber Collaboratory for help. Through their collaboration, Rippetoe now hopes to expand his business to also print flexible ankle braces. (Rippetoe holds a Bachelor of Science in Kinesiology from LSU and a Doctor of Physical Therapy from LSU Health Shreveport.)

– Photo courtesy of Bishop

Since joining the Collaboratory, Dixon has been exploring the idea of using virtual reality headsets as part of counseling and therapy.

Another project in the healthcare realm recently connected Shreveport small business entrepreneur and physical therapist Eric Rippetoe of Bishop with the Collaboratory team. Together, Ricard and Rippetoe created a custom knee brace for a Bishop client who plays college football.

“His leg was larger than my print bed,” said Rippetoe, who owns and operates his own 3D-printing equipment, but found himself in need of greater capabilities.

Ricard introduced him to the industrial 3D printer in the Cyber Collaboratory, which can create up to a one-meter cube.

“We had a few hiccups and ran out of filament mid-print, but Eric got his braces,” Ricard said. “I love the amount of experience I’m getting interacting with people like him and everyone else we meet through the projects we’re doing.”

“I initially didn’t think I was going to be able to do something like this in Shreveport, honestly,” he continued. “I expected to have to move away so I could actually do something with my 3D-modeling and printing skills, but now I feel like there’s a chance; staying in Shreveport is an option.”

“[LSUS Cyber Collaboratory] printers can also do custom circuit boards, which gave me the idea of integrating sensors into knee braces, for example. The sensor can then alert a player or coach or parent whenever the person wearing the brace has suffered a force that exceeds the limit for ACL tears. Each new tool is a new medium to create.”

Eric Rippetoe, founder of the Shreveport physical therapy company Bishop

This is because the Cyber Collaboratory acts like an incubator for technology-driven ideas, Rippetoe argued.

“Their printers can also do custom circuit boards, which gave me the idea of integrating sensors into knee braces, for example,” he said. “The sensor can then alert a player or coach or parent whenever the person wearing the brace has suffered a force that exceeds the limit for ACL tears. Each new tool is a new medium to create.”

Rippetoe plans on tapping other capabilities in the Cyber Collaboratory also. Their machines can 3D-print two different materials at the same time, which would allow Rippetoe to create fully flexible braces by printing a harder material around a soft material, like a scaffolding that then can be removed.

“Ankle braces must allow a great deal of movement, but custom-printing them without the help of the Cyber Collaboratory would be near impossible for me since flexible materials tend to sway, and if they do, the print is ruined,” Rippetoe said. “I think a lot of people are just starting to understand the value of 3D printing, because you can make almost anything super-quick, and the tools at LSUS are spurring innovation.”

LSUS student Matthew Dixon has been involved in projects integrating small Raspberry Pi computers into custom devices for computer vision and machine learning projects, including with the City of Shreveport.

Encouraging innovation in northwestern Louisiana and advancing student careers in technology was part of the reason Louisiana Economic Development (LED) contributed $1.2 million to a $3 million agreement with LSUS last November (led by LED FastStart, the nation’s premier state workforce training program) after the university had already invested $750,000 in the creation of the 10,000-square-foot Cyber Collaboratory as well as a design-thinking lab.

“Our administration is committed to ensuring that all our young people have ample access to the tools, programs, and training needed to compete in today’s marketplace,” said Governor John Bel Edwards at the announcement of the agreement.

He was greeted at LSUS by the director of the Cyber Collaboratory, Scott Isaacs, who fields new ideas from the surrounding Shreveport community for collaborative projects on a weekly, near-daily, basis.

“Other than helping the Air Force with mission-critical needs they’re having a hard time filling right now, we’re also collaborating with other industry partners and the City of Shreveport, with whom we’re working on a number of Smart City projects to help improve city services through technology, including machine learning and computer vision,” Isaacs said.

Last week, he was also sitting in the cockpit of the B-52 (best described by its full name, the Boeing B-52 Stratofortress) together with Ricard, making sure each of the scanned areas turned green on the screen by “painting in the data” the Air Force will use to develop the next stage of their virtual reality training program for B-52 pilots. The Cyber Collaboratory team will also create a physical model of the yoke, to be used as a custom controller.

“What I think has been working really well is that getting us to come out isn’t a long and arduous process with requisition and approvals up and down the chain,” Isaacs said. “They call, and we come out.”

Airmen from Barksdale Air Force Base use the LSUS Cyber Collaboratory for training and professional development.

Major Brandon Wolf, assistant director of operations for the 307th Operation Support Squadron at Barksdale and director of LR Werx, a “spark cell” and local counterpart of AFWERX, which is the main innovation arm of the U.S. Air Force, agreed.

“There is a big push for innovation and increased operational capabilities in the Air Force right now and LSUS has allowed us to experiment and explore what we might be able to do with new and rapidly advancing technology,” Major Wolf said. “Our goal is to fail fast, and what that means is not that we’re trying to fail, but try new things quickly to see if they work and not sink a bunch of money into projects or prototypes that might be outdated by the time we get them into our hands.”

“LSUS has allowed us to experiment and explore what we might be able to do with new and rapidly advancing technology ... in a period of eight to nine months, we’ve gone from ‘No one was even thinking of this’ to ‘Here’s my list of ideas.’”

Major Brandon Wolf, assistant director of operations for the 307th Operation Support Squadron at Barksdale and director of LR Werx

“That culture is changing, and in a period of eight to nine months, we’ve gone from ‘No one was even thinking of this’ to ‘Here’s my list of ideas,’” Major Wolf continued. “Once you start to improve, it highlights things you get used to in the day-to-day and don’t think of as problems. Then you realize, ‘if we only had this…,’ it would make our lives easier and we’d be more efficient. And with each thing you fix, there’s, ‘What else can we do?’ So, we’re going to be busy.”

The 3D scanner Ricard and Isaacs brought out to Barksdale Air Force Base was initially going to be a joint purchase by the LSUS departments of biology, kinesiology, history, and digital arts. But realizing how useful the tool could be to faculty, staff, and students in different disciplines across campus, the LSUS Foundation stepped in to cover the cost.

“This is an if-you-build-it situation where new tools spark new ideas,” Isaacs said. “We meet people by meeting people—they hear about how we’re helping the Air Force and come to us to see if we can help them with things, too.”

STRIKEWERX partnered with LSUS and the Cyber Collaboratory to help prototype this transporter erector jack stand cover for intercontinental ballistic missiles, or ICBMs.

While Isaacs, Ricard, and Dixon dive deeper into projects, LSUS is also working on integrating the tools and experiences available through the Cyber Collaboratory into the curriculum for all students. And not just students at LSUS. Through a partnership with the Caddo Parish School Board and the Cyber Innovation Center, the Cyber Collaboratory team will teach a month-long course to 20 Caddo students this June. Called Cyber Lit 1, it will incorporate 186 hours of classroom time and count as high school class credit.

“We’re excited to host this summer camp as a way to continue the development of young talent in this area,” said Julie Lessiter, vice chancellor of strategic initiatives at LSUS. “Having these students on our campus in the Cyber Collaboratory increases their exposure to new and innovative technology that will become common-place in industry within a few years. Our goal is to provide as many learning opportunities as possible so students can be successful in their lives and careers in our increasingly digital economy.”