CIMM Integrated Computational Materials Engineering (ICME)

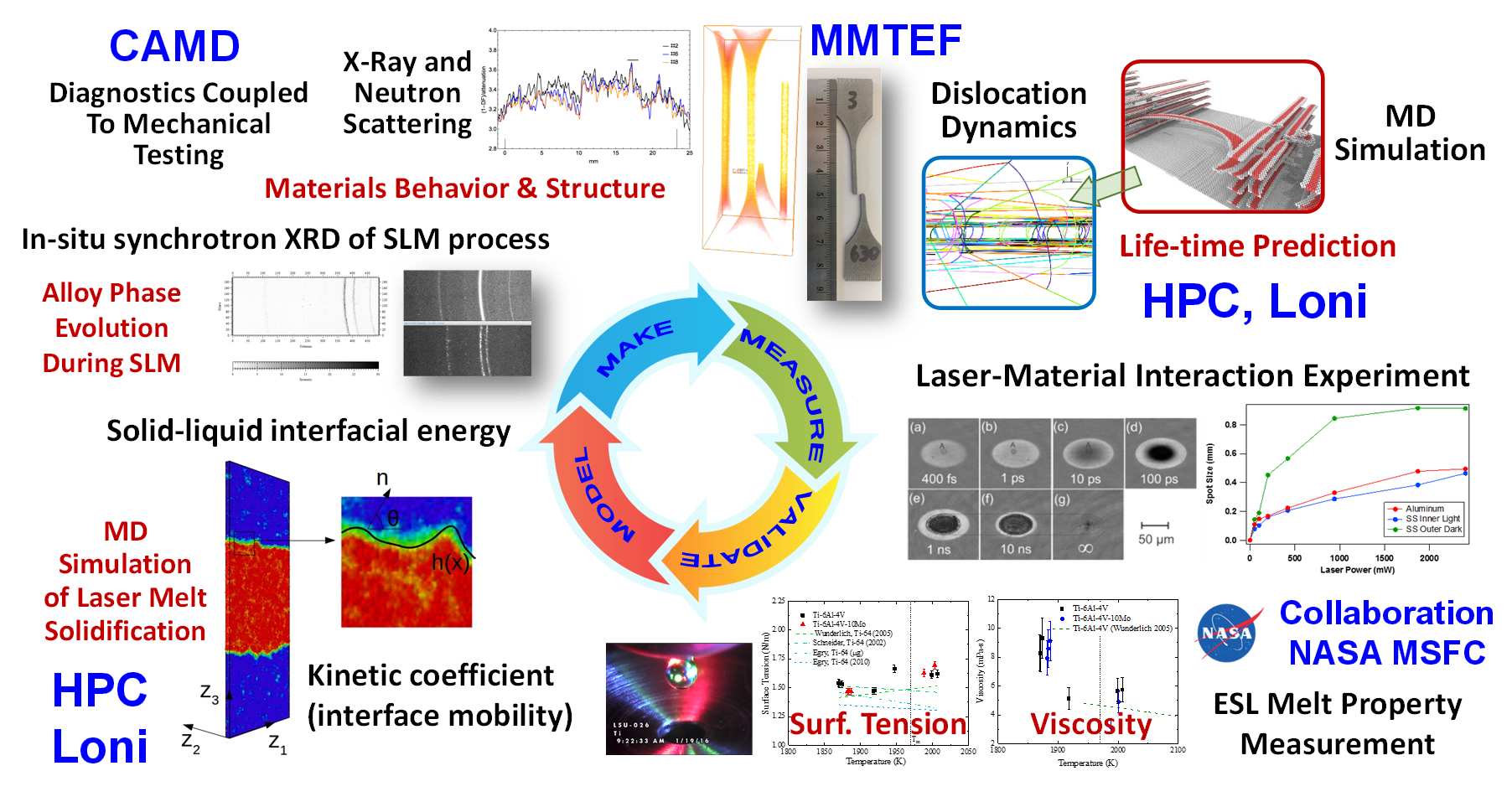

The Consortium for Innovation in Manuafcturing and Materials (CIMM) takes an Integrated Computational Materials Engineering (ICME) approach in meeting the technical and scientific challenges associated with its science and technology thrust areas. This "Model-Make-Measure-Validate" closed-loop approach is illustrated below for some current CIMM projects.

A broad range of research resources are brought to bear in order to enable the ICME approach. The CIMM Core User Facilities (CUF), which comprise of the Shared Instrumentation Facility (SIF) , the Advanced Manufacturing and Machining Facility (AMMF), the Materials manufacturing and Machining Facility (MMTEF) and the Institute for Micromanufacturing (IfM) provide state-of-the-art experimental resources, along with the synchrotron facility at the Center for Advanced Micro-structures and Devices (CAMD). In addition, LSU High Performance Computing (HPC) and the Louisiana Optical Network Infrastructure (LONI) provide ready access to formidable (peta-scale) computational resources for simulations.

Powder Bed Fusion (PBF) 3D-Printing

Understanding and correlating Powder Bed Fusion (PBF) process to qualification and properties of manufactured outcomes through combined multiscale numerical modeling, simulation and experimentation by employing state-of-the-art in situ diagnostics.

Team Members: Shengmin Guo, Wenjin Meng, Phillip Sprunger, Shuai Shao, Louis Haber, Leslie Butler (LSU); Jonathan Raush (U. L. Lafayette); Dentcho Genov (LATech).

Copyright © LSU 2018

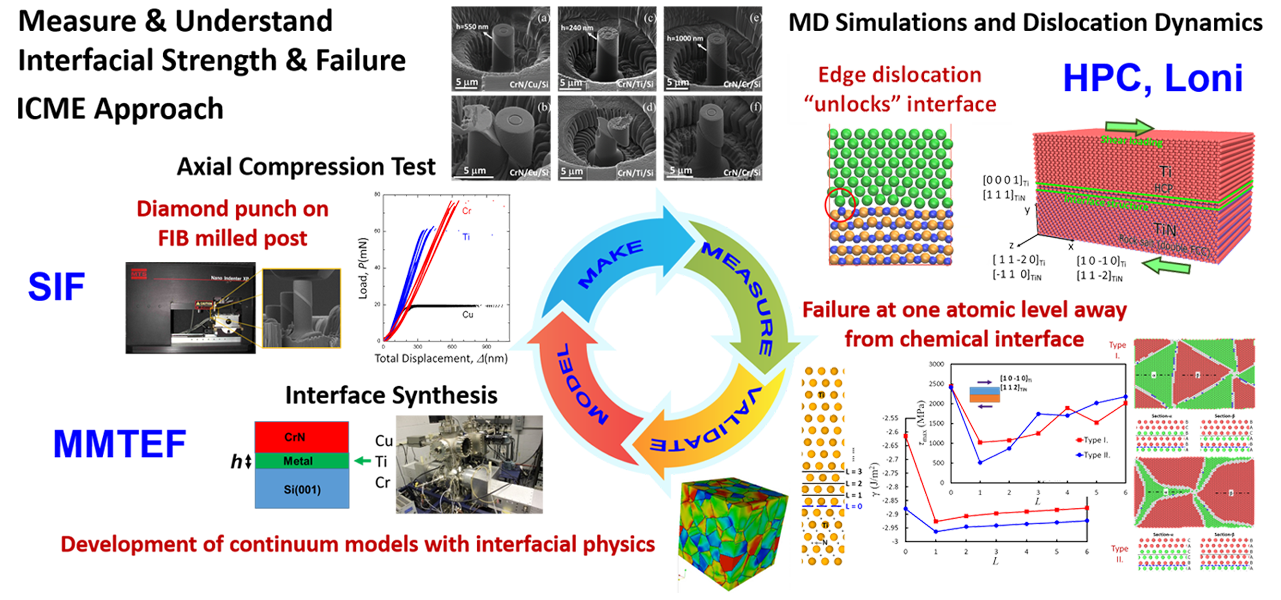

Interface Engineering and Qualification

Understanding and quantifying intefacial strength and failure is essential to the engineering of strong and resilient interfaces for a broad range of applications including coatings and heterogeneous material joining. This challenge is met through combined multiscale numerical modeling, simulation and multiscale experimentation.

Team Members (LSU): Shuai Shao (Multiscale Simulations) and Wenjin Meng (Experiments).

Copyright © LSU 2018

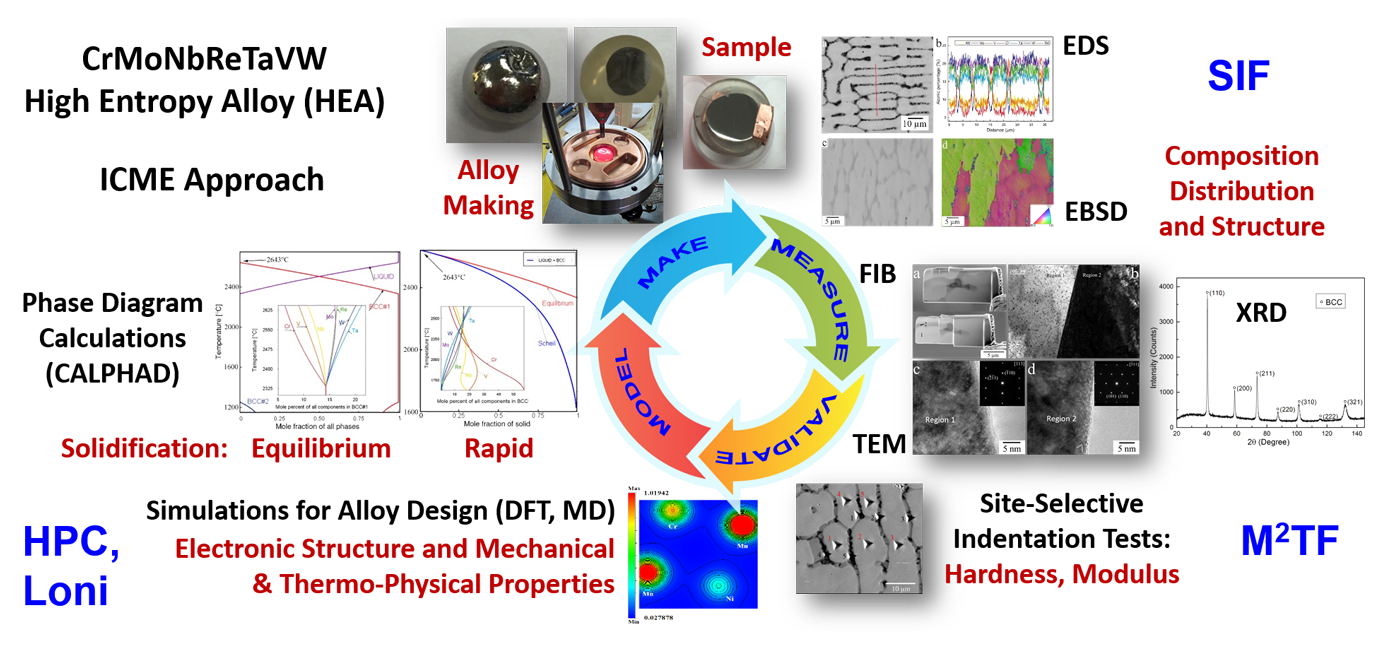

High Entropy Alloys (HEA) for Additive Manufacturing (AM)

High Entropy Alloys (HEA) are alloys with multiple element constituents at relatively high content of each. Development of HEAs for addive manufacturing applications is undertaken employing a combination of multiscale numerical modeling, simulations, alloy making and multiscale experimentation for understanding and qualifying the outcome.

Team Lead: Shengmin Guo (LSU); Investigators: Wenjin Meng, Phillip Sprunger (LSU); Shizhong Yang (Southern University); Daniela Mainardi, Ramu Ramachandran (LATech); Pedro Derosa (Grambling State U.)

Copyright © LSU 2018